Grip inserts for safe clamping

Our grip inserts offer a safe reliable torque transmission when clamping

cast or forged blanks. We also offer a solution for the clamping of warp-sensitive workpieces, which must be clamped safely despite low clamping forces.

cast or forged blanks. We also offer a solution for the clamping of warp-sensitive workpieces, which must be clamped safely despite low clamping forces.

Blessing Grip inserts offer the following advantages:

Quality that withstands hard handling for a long time

STANDARD EXECUTIONS

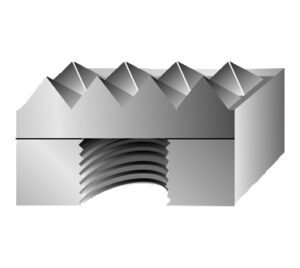

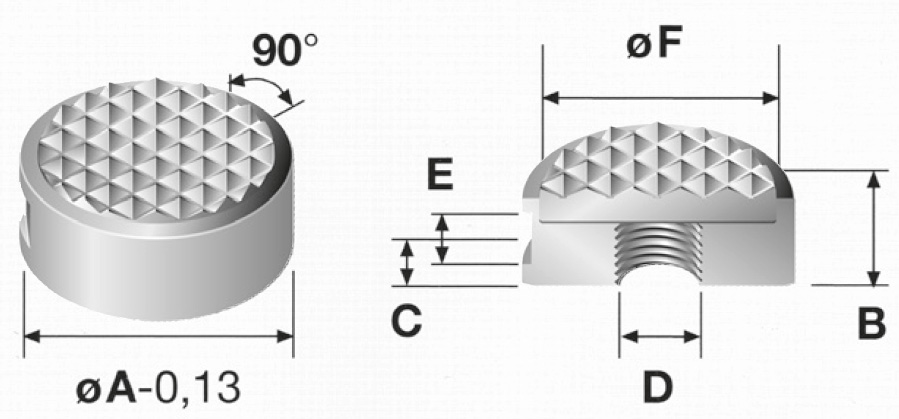

SERIE G Type

Carbide grip inserts, brazed, round

| ORDER NO./TYPE | A | B | C | D | E | F |

| G 06 | 6 | 10 | – | M3 | – | 5 |

| G 08 | 8 | 10 | 4,5 | M4 | 5 | 6 |

| G 10 | 10 | 10 | 4,5 | M5 | 5 | 8 |

| GCT 841 | 12,7 | 9,5 | 4,5 | M5 | 5 | 9,5 |

| GCT 4 | ? | ? | ? | ? | ? | ? |

| GCT 4A | 12,7 | 12,7 | 4,5 | M6 | 5 | 9,5 |

| GCT 4C | 12,7 | 16,5 | 4,5 | M6 | 5 | 9,5 |

| GCT 5 | 15,8 | 9,5 | 4,5 | M6 | 5 | 13 |

| GCT 6 | 19 | 9,5 | 4,5 | M6 | 5 | 16 |

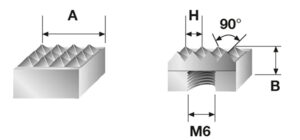

SERIE G Type

Carbide grip inserts, brazed, square

| ORDER NO./TYPE | A | B | H |

| GTC 870 F square | 12,7 x 12,7 | 9,5 | 2,2 |

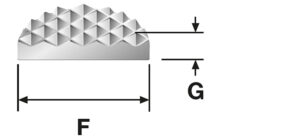

SERIE CT Type

Solid carbide for soldering, round

| ORDER NO./TYPE | F | G |

| CT1 | 5 | 3,2 |

| CT2 | 6 | 3,2 |

| CT3 | 8 | 3,2 |

| CT4 | 9,5 | 3,9 |

| CT5 | 13 | 3,9 |

| CT6 | 16 | 3,9 |

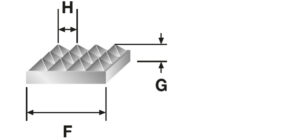

SERIE CT Type

Solid carbide for soldering, square

| ORDER NO./TYPE | A | B | H |

| CT 8 F square | 10,2 x 12,5 | 3,2 | 2,2 |

Customised designs / special developments

If no standard grip insert is suitable, Blessing can produce customised grip inserts , individually adapted to the respective requirement. This applies to both the shape and the material. Blessing Special Grip inserts are available, in steel or solid carbide. Examples of such custom-made products are listed in above chart.

All sizes are in mm.