Scale of a perfect Blessing solution: Your individual requirements

Chuck

With two, three or more jaws, centric or compensating clamping or adapted to the given clamping contour. Multi-point clamping for deformation-sensitive components. Low-maintenance versions (long-term oil filling) upon request. Quick change systems for workpiece contacting parts are available.

Mandrels and collets

For clamping in boreholes and on outside diameters, or with several clamping points.

With or without pull-down action.

Single row or multiple rows.

Can be combined with additional functions, such as planar clamping or balancing clamping jaws.

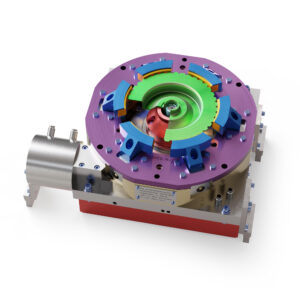

Balancing chucks

Maximum run-out and repeat clamping accuracy.

For horizontal and vertical balancing spindles.

Upon request: with additional functions, such as lifting and twisting units for eliminating any imbalance.

Cylinders / Rotary distributors

Cylinders with up to three independent pistons for power-operated chucks. Distributors with any number of channels. Media such as hydraulic oil, lubricating oil, blowing air or cooling lubricants can be combined. Sealed for low-speed devices, sealless for high-speed devices. Integrated stroke monitoring systems upon request.

Fixtures

Can be equipped for stationary use with any number of clamping, centring, alignment and damping functions. Available with integrated actuation units (hydraulic, pneumatic, electromechanical) upon request.

Grip inserts

Can be used for all types of clamping jaws. For improved torque transfer without increasing the clamping force. A fast exchange solution. Standard sizes are available ex stock.

Basis of perfect Blessing solutions: DevelopmentDesignProduction

Blessing’s formula for success is the approach from development to the finished clamping device. This is usually based on a proven 3-phases concept.